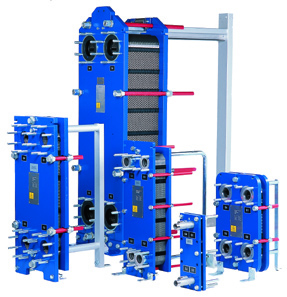

Alfa Laval gasketed heat exchangers

Reliability in a single step

The heat transfer efficiency and degree of process control offered by a PHE depend partly on the thickness of the plates. In today’s advanced Alfa Laval units, plates as thin as 0.4 mm, normally in stainless steel, offer highly efficient heat transfer and impressive strength. Each plate is pressed in a single step in a hydraulic press exerting a pressure of up to 40,000 tons. Thus all plates are identical, minimising the risk of distortion and leakage when hundreds are stacked together in a PHE. When assembled with gaskets, the metal-to-metal contact points on the plates create a flexible, yet mechanically stable construction that can withstand enormous stress.

The pattern of performance

The corrugated pattern on the plates gives parallel flow and strength. The “chocolate” pattern of the distribution area ensures even distribution of the fluid over the plate surface, while the herringbone pattern in the main heat transfer area creates maximum turbulence. Together, these features ensure high heat transfer efficiency and eliminate dead spots that can lead to scaling and corrosion.With parallel flow, only one plate type and one gasket type are required in the heat exchanger. This means fewer spare parts and simpler installation and maintenance. As the plate corrugations are fully supported diagonally across the entire surface, a higher design pressure can be achieved, or plates can be made thinner.

• Wide range of products for every need

• Extremely reliable

• Highly service-friendly

The seal of approval

Our ongoing development and testing of gasket materials for specific duties, ensure that Alfa Laval gaskets last longer. Made from nitrile (NBR) or EPDM, they are moulded in one piece, guaranteeing exact gasket geometry. Our “roof-top” gasket profile produces a highly efficient seal, minimising the risk of leakage. The groove on the plate and the gasket are a perfect match, ensuring full support for the gasket and eliminating the risk of a gasket blow-out. The gasket groove design ensures minimum contact between the media and the gasket, another factor that makes our gaskets last longer.

Bonded for life

Alfa Laval gasket fastening solutions guarantee a perfect result. The Alfa Laval glue-free clip-on gasket makes re-gasketing fast and simple. Where the PHE is opened frequently, glued gaskets are an excellent solution. Alfa Laval uses two-component, oven-cured epoxy glue to bond the gasket to the plate. This more than doubles gasket life-time compared to using standard rubber glues.

Designed with service in mind

Alfa Laval gasketed PHEs of all sizes can be opened quickly and easily for inspection and gasket replacement by one man using standard tools. They are reassembled just as easily. Our large units feature Alfa Laval’s 5-point alignment system. Precise positioning of the plates horizontally and vertically ensures efficient sealing throughout the plate pack. A roller on the pressure plate, and bearing boxes on the four tightening bolts, make opening and closing an easy task. Simpler in design, our smaller PHEs are equally service-friendly, while keeping costs to a minimum. During reassembly, alignment of the plate pack is achieved using the round carrying and guide bar. Corner guides lock the plates in position and ensure perfect final alignment.